SDC Inc.

SDC Inc.Request A Quote

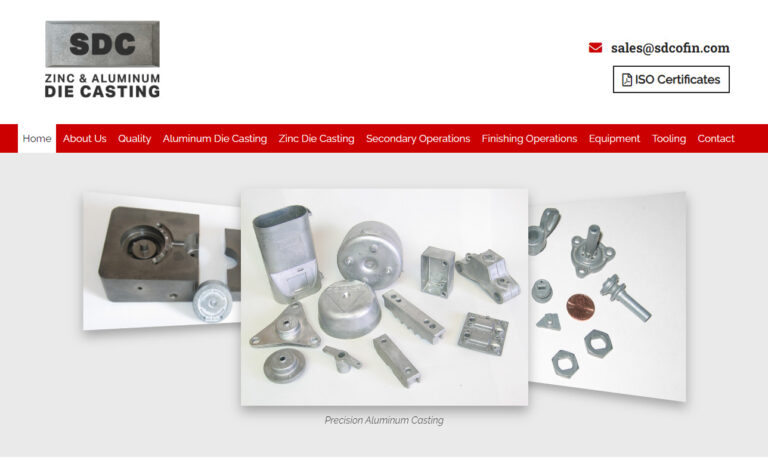

Sullivan, MO | 573-468-3107SDC Inc., headquartered in Sullivan, Missouri, is a reputable manufacturer specializing in the production of die castings. With a strong commitment to quality and continuous innovation, we have established ourselves as a leading provider of high-quality die castings. Our dedication to excellence is reflected in the premium metals we use and the certified heat treatment processes employed in creating all of our products. At SDC, we strive to deliver the highest quality products and services to our customers. Our team is passionate about upholding the highest standards of quality in every aspect of our operations. We continuously encourage innovation, both in our manufacturing processes and in our customer service, to exceed expectations and stay ahead of industry trends. One of our core strengths lies in our ability to meet exact specifications. We work closely with our clients to understand their unique requirements and ensure that our die castings are manufactured to precise specifications. Our advanced manufacturing facilities, coupled with our experienced engineers and technicians, enable us to produce complex and intricate die castings with exceptional accuracy and precision. In addition to our primary die casting capabilities, SDC offers a comprehensive range of secondary operations to provide complete solutions to our customers. Our tooling services ensure that we have the necessary molds and equipment to manufacture die castings that meet specific requirements. We also provide machining services, allowing us to perform precise operations on castings to achieve the desired dimensions and finishes. Moreover, our burnishing services enhance the surface appearance and provide a smooth finish to the die castings. At SDC, we understand that longevity and durability are crucial factors in the success of our customers' products. That's why we emphasize quality throughout our manufacturing processes, from the selection of premium metals to the implementation of certified heat treatment techniques. We are committed to creating die castings that not only meet the highest quality standards but also provide long-lasting performance. When you choose SDC as your die casting partner, you can expect exceptional quality, reliability, and a commitment to meeting your specific needs. Our motto, "To make it last, make it SDC," reflects our dedication to producing durable and reliable die castings that stand the test of time. Contact us today to discuss your die casting requirements, and let SDC demonstrate how our products and services can contribute to the success of your projects.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services