The metal-forming process known as aluminum die casting can create intricate aluminum pieces. Before melting entirely, aluminum alloy ingots are heated to extremely high temperatures. The liquid aluminum is then injected under high pressure into a steel die cavity, also known as a mold. Finally, the two components of the die are separated to reveal the cast aluminum component after the molten metal has solidified.Read More…

Precision die castings plus a multitude of related services, including engineering, designing, machining, finishing and assembly, occur at A and B Die Casting. Specializing in low to medium volume solutions, we also offer competitive prices.

Carteret Die Casting has grown from a two man and two machine operation in a tiny 1000 square foot space, to a company that has over 20 state-of-the-art equipment.

Precision Die Casting since 1950. Aluminum die casting and zinc die casting for aerospace, electronic, commercial industries. Turnkey operations from design or your blue print to assembly.

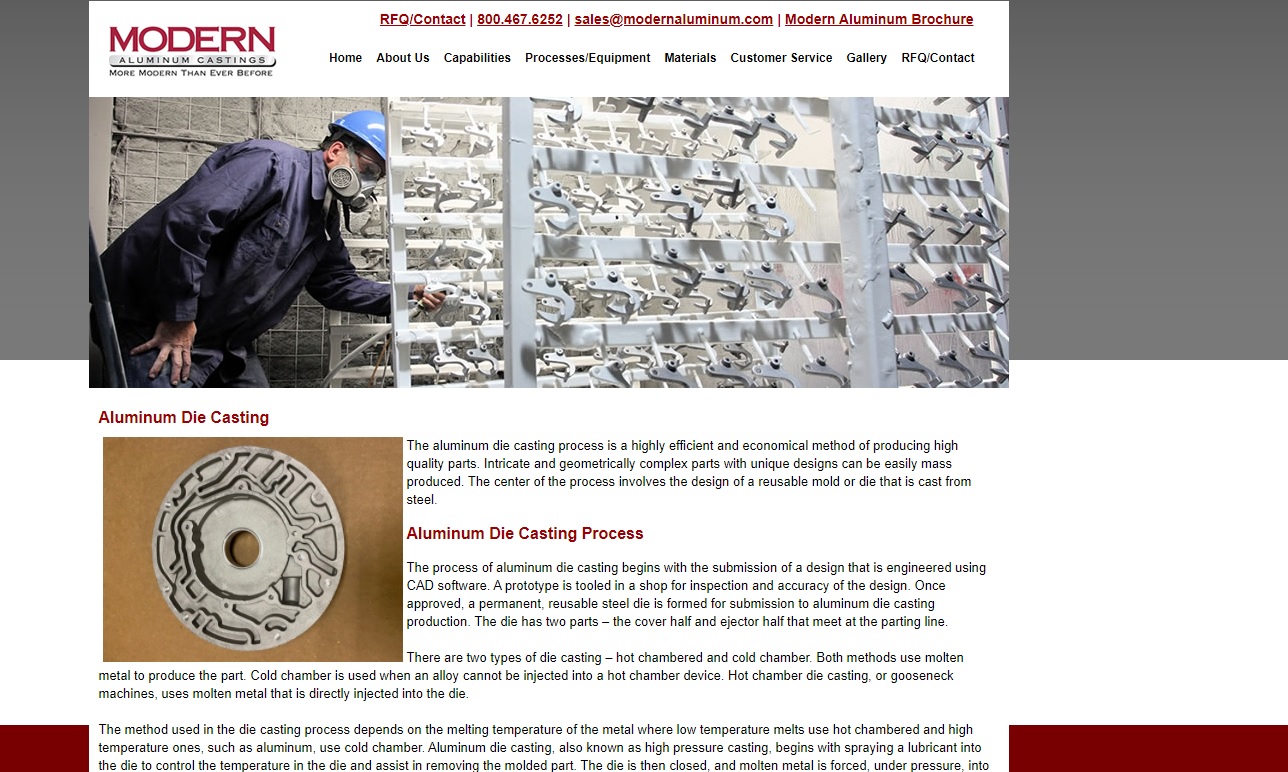

Modern Aluminum Castings offers customers full-service die castings and related capabilities from design to delivery. We work with a large variety of metal options, making us your one-stop source.

Carpenter Die Casting is more than just a die-casting manufacturer; we are your reliable partner in bringing your ideas to life. With decades of experience, a dedication to quality, and a proven track record, we stand ready to contribute our expertise to your next project. Discover the Carpenter Die Casting difference – where innovation meets tradition, and excellence is our standard.

More Aluminum Die Casting Companies

Aluminum Die Casting Process

Making and Getting the Die Ready

A steel alloy is first used to make a die. Die designs are carefully chosen to guarantee accurate filling and removal of the aluminum product. When it's time to extract the aluminum product, at least two components in each die are separated after being put together during the casting process. More complicated dies will include many pieces to make holes and other precise shapes.

The die has a hole in one area where aluminum is injected to fill a three-dimensional cavity. Although a die can be used tens of thousands of times, how long it will last depends on the part's design, the type of alloy used, and the caliber of the part being produced. The die is constructed, and its components are then greased and clamped together to prepare for filling.

Adding Aluminum Injection

To fill the mold, molten metal is pumped into the die's hole. This part of the process only takes a few seconds due to the high pressure to guarantee that the aluminum quickly adheres to all the intricacies of the die.

Aluminum Cooling

The die remains held together after casting as the aluminum cools. A powerful product can be made by cooling an aluminum alloy sufficiently that it solidifies into a single substance. The die can be unclamped to reveal a finished object that is exactly the shape of the die after cooling. Thousands of goods can be produced by repeating this process as often as necessary.

Polishing and Finishing

Die-cast aluminum pieces frequently only need little machining, and various surface finishing alternatives exist. By casting standards, die casting has a very good surface polish, although it is still possible for there to be flaws, such as metal seams where the mold halves connect. Sanding, sandblasting, or orbital sanding can smooth out a rough surface or other flaws that are unsuitable for the part.

Shot peening, a cold working technique, is frequently used on die cast aluminum to increase fatigue resistance. Alternatively, a protective or ornamental coating, such as a powder coat, might be added to the finished part. After casting, the pieces can undergo additional adjustments like drill tapping.

What to Consider When Designing an Aluminum Die Cast

First, the mold needs to separate and release the solidified metal component. A separation line must be considered in the initial phases of die design since it designates the point at which the two sides of the mold separate. The location of injection locations is an additional essential factor. In situations where the molten metal would otherwise solidify before reaching every gap in the die, the die can be built with several injection points.

Applications of Aluminum Die Casting

Automotive, construction, hardware, marine, aerospace, and plumbing are just a few sectors that benefit from aluminum castings. For example, their dimensional stability and heat resistance make them the ideal match for automobile cast valve covers. In addition, because of their great resistance to corrosion and high temperatures, they perform well in manufacturing hardware and tools.

Advantages of Aluminum Die Casting

Strength and Lightness

Even at very low temperatures, aluminum is a remarkably strong metal. It is also lightweight, making it the ideal material for dependability and usability. Aluminum can sustain pressure within a light frame, especially for producing goods with thin walls. Furthermore, die casting frequently eliminates the requirement for joining or fastening a part together. Since the entire product was cast in a single piece, its strength is determined by the strength of the alloy rather than being constrained by possibly flimsy fasteners.

Customizability

Aluminum may be easily molded into intricate and complex forms using the high-pressure die-casting method, so the finished items will be what is exactly needed. Aluminum casting also allows for variations in part wall thickness, allowing lean production as per requirement.

Higher Production Rates

Aluminum alloys are simple to work with, allowing for quicker parts production than other metal alloys. In addition, it takes less machining than other casting methods because of the pressure and speed with which the aluminum is blasted into the die.

Corrosion Protection

Atoms of aluminum have a strong attraction to oxygen. As a result, aluminum atoms join with oxygen to form an exterior layer of aluminum oxide as soon as aluminum or its alloys are exposed to the atmosphere. In addition, aluminum oxide's chemical structure changes when it comes into contact with water, preventing it from reacting with the water.

Choosing the Right Aluminum Die Casting Company

To make sure you have the most positive outcome when selecting an aluminum die casting company, it is important to compare several businesses using our directory of aluminum die casting companies. Each company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with this business for more information or request a quote. Review each aluminum die casting company website using our proprietary website previewer for a better idea of what each business specializes in. Then, use our simple RFQ form to contact multiple aluminum die casting companies with the same form.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services