Die casters are metal shaping tools; they are a variety of metal casting utilities, all of which use heat and pressure to turn raw metal materials into usable products. Read More…

Precision die castings plus a multitude of related services, including engineering, designing, machining, finishing and assembly, occur at A and B Die Casting. Specializing in low to medium volume solutions, we also offer competitive prices.

Carteret Die Casting has grown from a two man and two machine operation in a tiny 1000 square foot space, to a company that has over 20 state-of-the-art equipment.

ZETWERK provides high quality die-cast components produced using range of materials including aluminum, zinc, copper, brass and bronze alloys. We also perform necessary secondary operations on the die-cast parts such as finish machining, surface treatment etc. ZETWERK is ISO 9001:2015 and AS9100D certified. Our die-casting plants are IATF 16949:2016 certified.

Precision Die Casting since 1950. Aluminum die casting and zinc die casting for aerospace, electronic, commercial industries. Turnkey operations from design or your blue print to assembly.

Modern Aluminum Castings offers customers full-service die castings and related capabilities from design to delivery. We work with a large variety of metal options, making us your one-stop source.

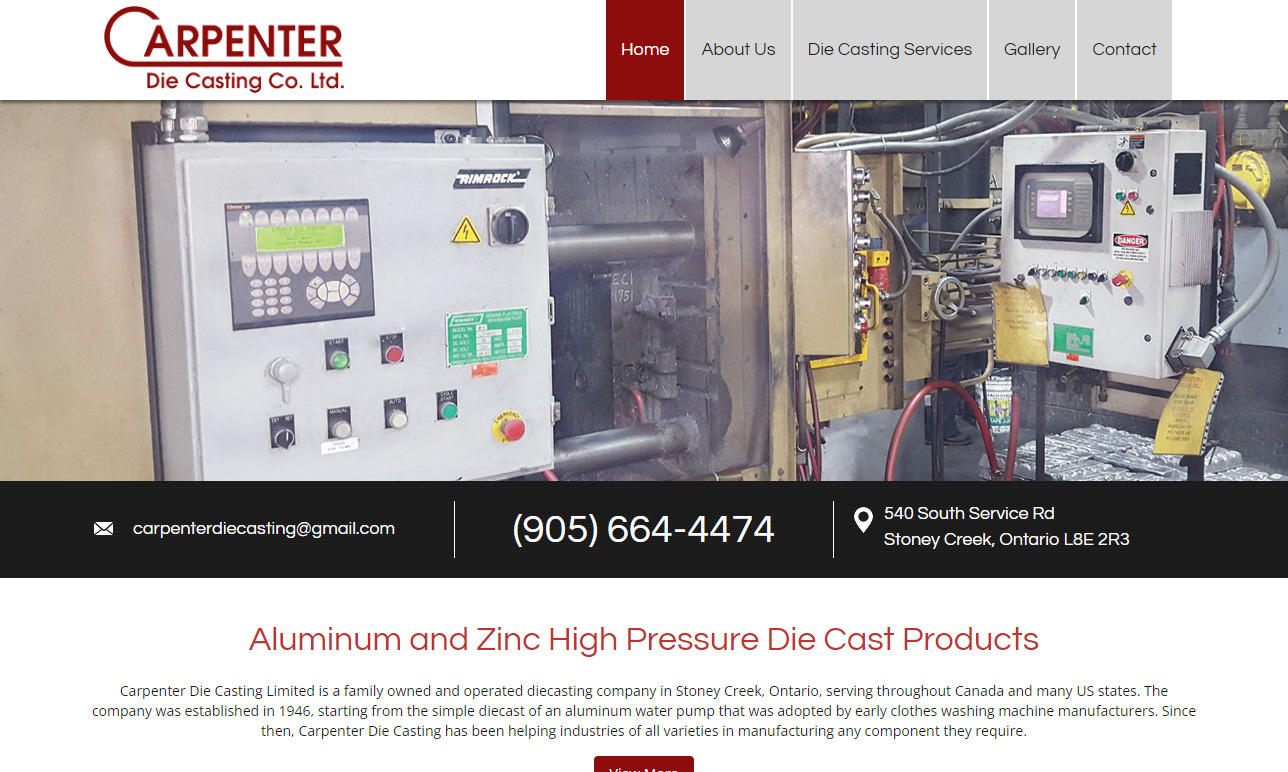

Carpenter Die Casting is more than just a die-casting manufacturer; we are your reliable partner in bringing your ideas to life. With decades of experience, a dedication to quality, and a proven track record, we stand ready to contribute our expertise to your next project. Discover the Carpenter Die Casting difference – where innovation meets tradition, and excellence is our standard.

We specialize in producing high-quality die castings using aluminum alloys. Our extensive product line includes components for various industries, such as automotive, aerospace, electronics, appliances, and more. From intricate and complex parts to large-scale castings, we have the expertise to deliver precise and reliable solutions. With years of experience in die casting, we offer a...

More Die Caster Companies

Die casting is one of the most widely used metal forming processes because of the precision with which it can create quality metal products to precise specifications in large volumes in a relatively short period of time. Die cast products can be found throughout industry and commerce.

The automotive industry makes extensive use of die casters in the production of engine blocks and aluminum valve covers. In commercial settings, die cast materials are important components in door access systems, cleaning tools, HVAC equipment and in many other capacities. Die cast products can even be found in consumer products contexts; plumbing components like pipe connectors are often die cast. Die casters are employed at metal forming operations, often in tandem with other metal shaping processes and sometimes other metal casting processes. Among all metal shaping processes, die casting is one of the most efficient, cost-effective and precise ways to create shaped metal products.

Die casters can produce metal shapes out of zinc, aluminum, magnesium, tin, lead, copper and several other metals. Some die casters also have extra parts, such as removable slides and cores, to produce holes, threads and other desired shapes in the casting. The die casting process involves heating a metal beyond its melting point, pressurizing it and forcing it into a mold. Once in the mold, the molten metal takes the shape of the mold. It is them allowed to cool and harden.

Dies are either air or water-cooled; the cooling of the die provides for quick cycling and is one of the factors in the high rate of production that die casting offers. It also gives a fine grain structure and superior strength and finish to the metal castings. Die casters are useful for many reasons. First, they are efficient, economical, and offer a wide range of durable shapes and components. Little or no machining is required after a part is die cast because the process provides very close tolerances for even complex shapes. Also, die casters are dimensionally stable and heat resistant with the ability to retain the strength of an alloy. When properly applied and maintained, die casters can provide companies with quality metal shapes for many years.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services