The metal casting procedure is the earliest and most popular means of manufacturing designs in certain shapes. It is the first stage in manufacturing many products. Read More…

Precision die castings plus a multitude of related services, including engineering, designing, machining, finishing and assembly, occur at A and B Die Casting. Specializing in low to medium volume solutions, we also offer competitive prices.

Carteret Die Casting has grown from a two man and two machine operation in a tiny 1000 square foot space, to a company that has over 20 state-of-the-art equipment.

Precision Die Casting since 1950. Aluminum die casting and zinc die casting for aerospace, electronic, commercial industries. Turnkey operations from design or your blue print to assembly.

Modern Aluminum Castings offers customers full-service die castings and related capabilities from design to delivery. We work with a large variety of metal options, making us your one-stop source.

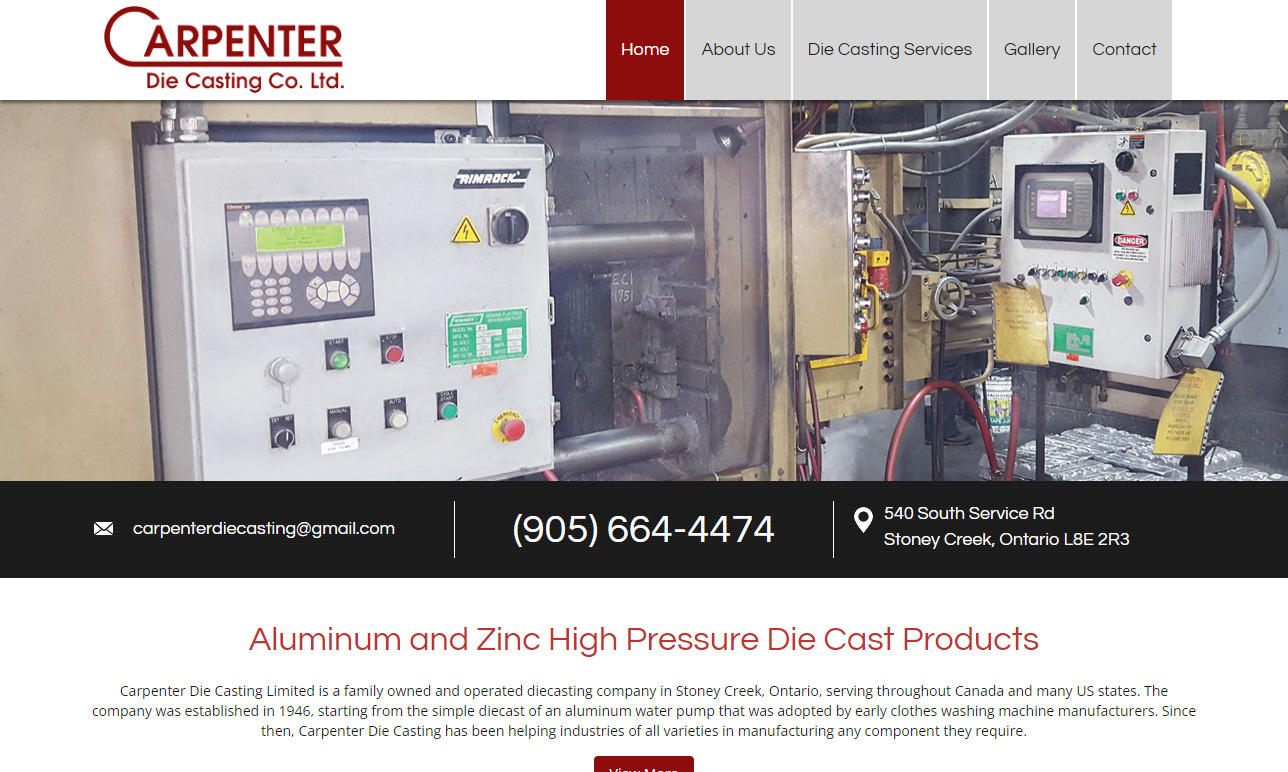

Carpenter Die Casting is more than just a die-casting manufacturer; we are your reliable partner in bringing your ideas to life. With decades of experience, a dedication to quality, and a proven track record, we stand ready to contribute our expertise to your next project. Discover the Carpenter Die Casting difference – where innovation meets tradition, and excellence is our standard.

More Metal Casting Companies

What are Metal Castings?

Casting is created from any meltable metal and can have any form the designer wants. The castings can be produced in dimensions ranging from a few millimeters to many meters and may weigh from a few grams to several tons.

Products with multifaceted shapes, hollow sections, multifaceted internal cavities, and unevenly curved surfaces made from metals that are hard to machine are simple to produce with the casting procedure.

Stages of Metal Casting Process

The following are the processes of producing metal casting:

Pattern Making

- Patterns are prepared as directed by the drawing of the casting acquired from the planning stage and in accordance with the molding process.

- The objects of the pattern are chosen based on factors like the number of castings needed and the surface finish required.

- The materials utilized for pattern making are metal, wood, or plastics.

Molding and Core Making

- The patterns are delivered to the molding step, where molds are made in either sand or another material. A pattern is used to produce a cavity of the required shape.

- To create a hollow part, cores are made in core boxes. The cores and molds are baked to convey strength and finally joined for pouring. The molding may be carried out either by hand or with the aid of machines.

- Proper mold design for the flow of liquid metal is essential for the production of accurate castings.

Melting and Casting

- Metal with the proper composition is melted in the appropriate furnace.

- Liquid metal is ladled into the molds. The molds are then left to cool, and the liquid metal solidifies in the mold.

- Castings are taken out by breaking the molds before they are delivered to the cleaning section.

Fettling

- In the fettling step, the adhering sand and unnecessary projections from the metal are removed. The full surface of the castings is made uniform and clean.

- Some castings require heat treatment, which is carried out during this stage only.

Testing and Inspection

- The inspector tests and inspects the castings to guarantee that they are flawless and conform to the required specifications before dispatching them from the foundry.

- If defects are present in the castings, they must be completely rejected.

Types of Metal Casting Processes

The following are the four metal casting processes types utilized for large-scale production:

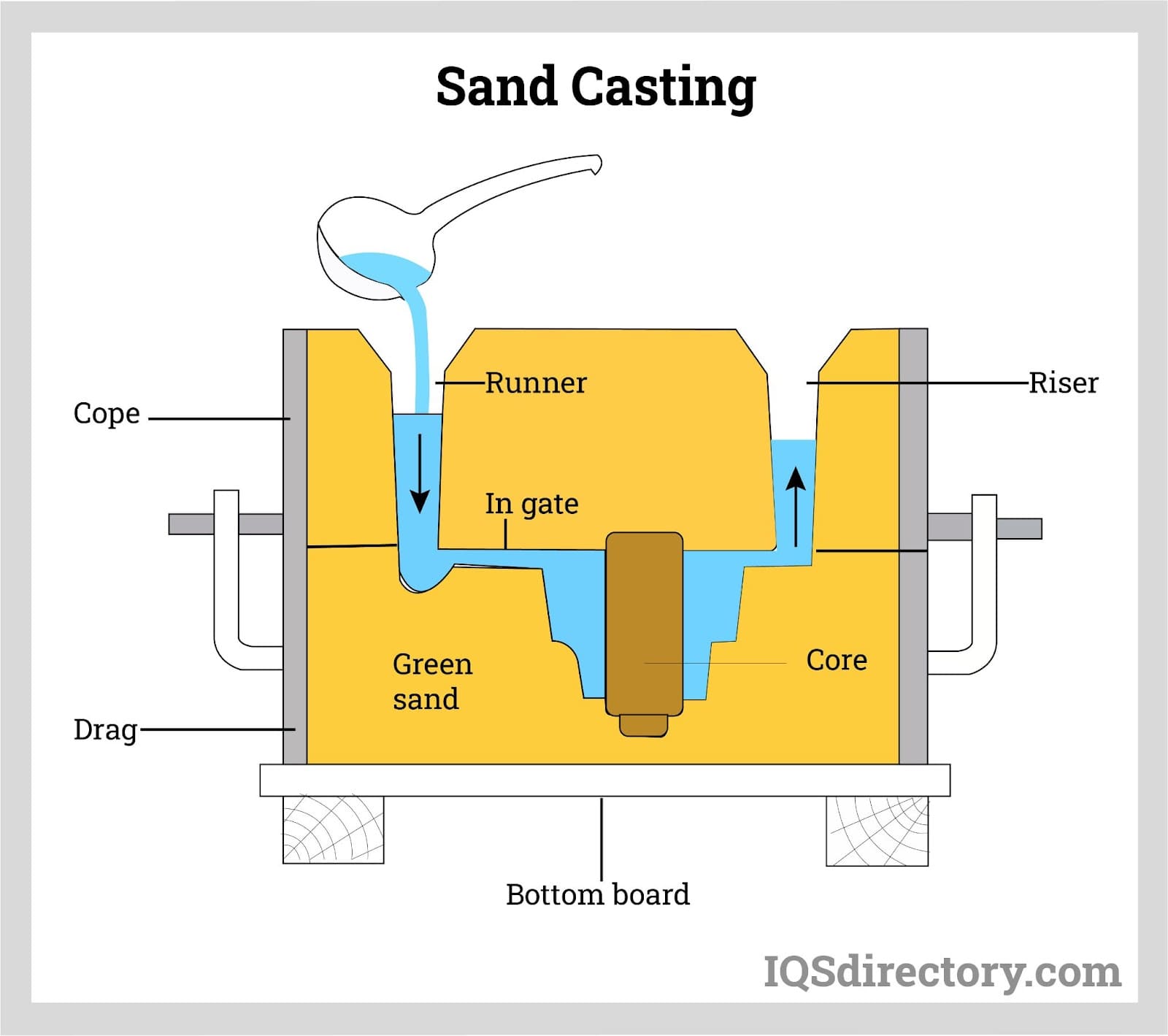

Sand Casting

Sand casting is the most widely utilized type of metal casting process. This is a permanent pattern-casting procedure that uses a dispensable mold. The sand casting procedure involves the usage of a furnace, pattern, metal, and sand mold.

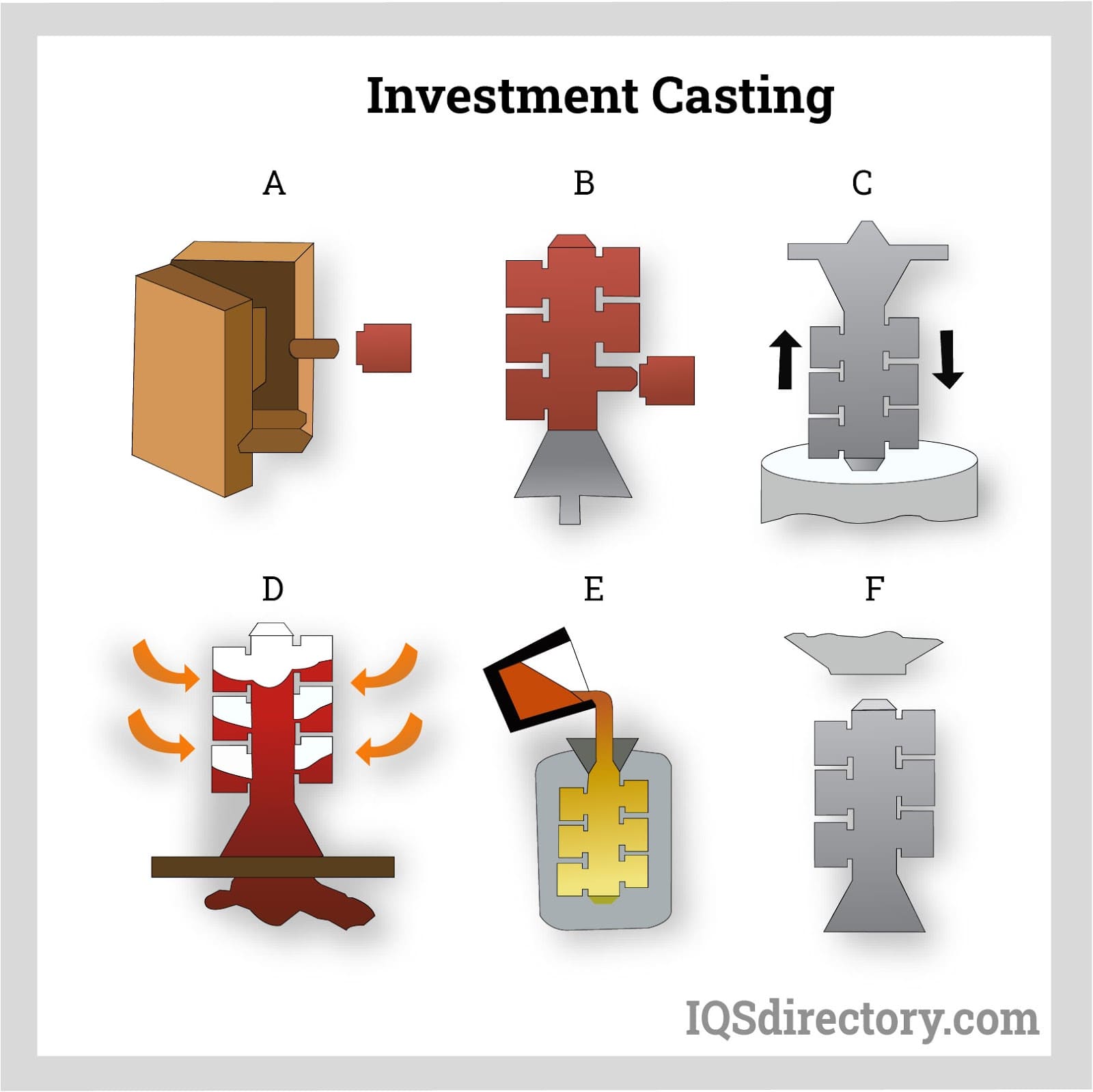

Investment Casting

The sequence of actions in shell investment castings is given below:

- Fabrication of a master pattern

- Fabrication of master dies

- Preparation of wax patterns

- Assembly of wax patterns

- Coating of a cluster

- Producing the final coat of refractory material

- Hardening of layers

- Melting of wax patterns

- Preheating the mold

- Filling the hot mold

- Cleaning the casting

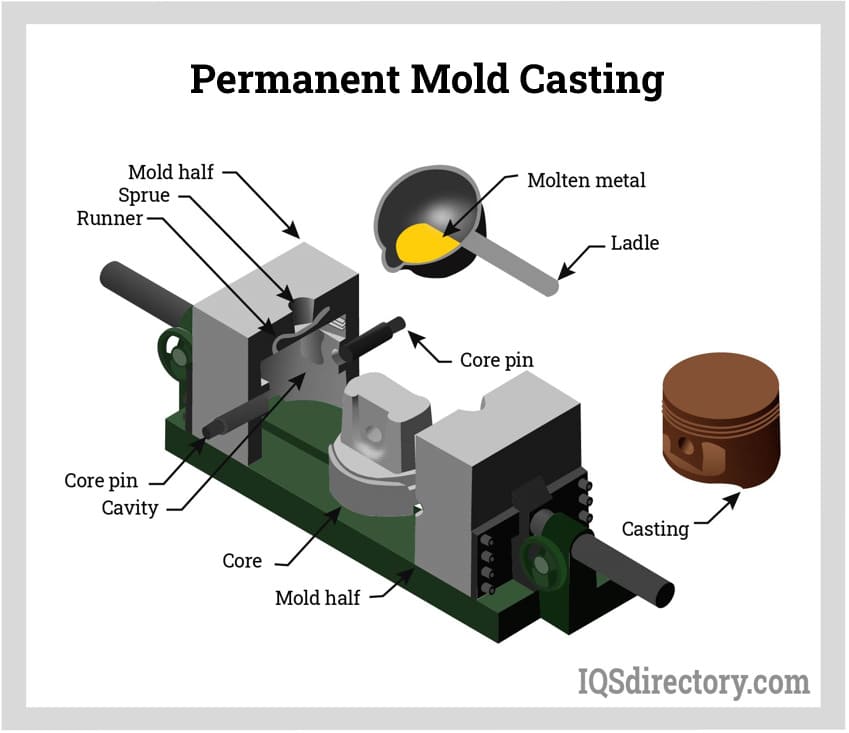

Permanent Mold Casting

There are many permanent mold casting procedures, some of which are listed below:

- Gravity feed permanent mold casting

- Low-pressure permanent mold casting

- Die casting

- Centrifugal casting

- Continuous casting

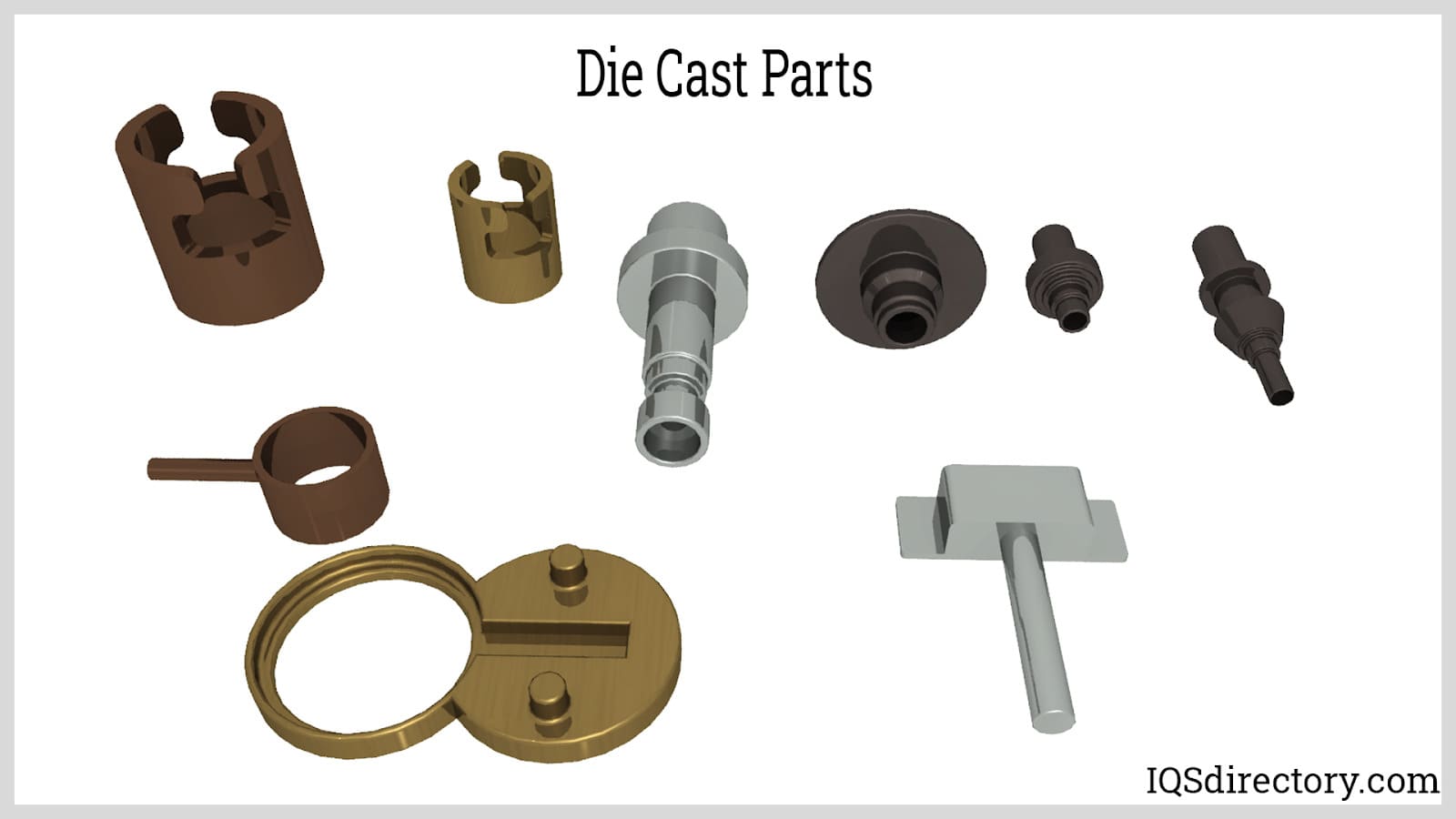

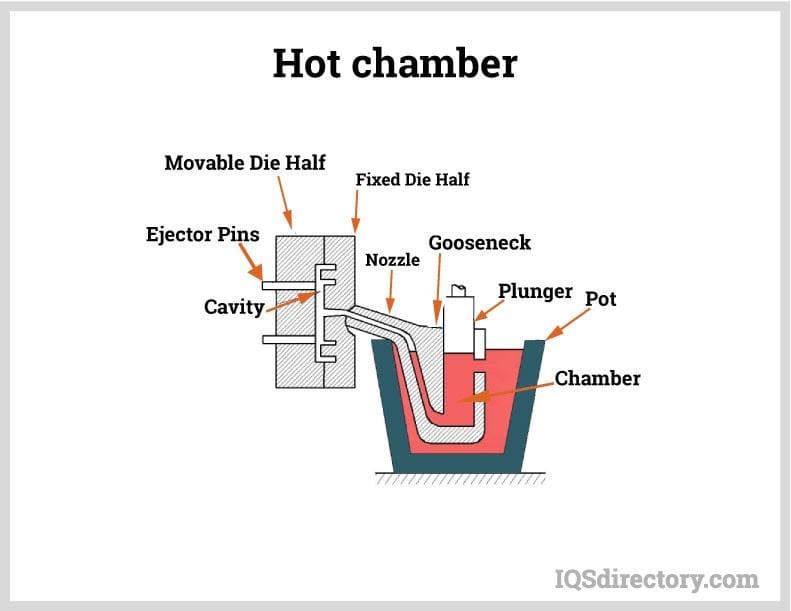

Die Casting

Die casting is a very commonly used permanent mold casting procedure. It is used to manufacture many parts of home appliances like fans, stoves, toys, motors, etc.

The surface coating and tolerance of die cast components are so accurate that almost no post-processing is required. Die casting molds are costly and require a substantial lead time to construct; they are usually called dies.

Advantages of Metal Casting Process

Below are some of the advantages:

- The budget involved in the casting procedure is lower compared to other manufacturing processes.

- Very heavy and large parts that are hard to construct with other manufacturing methods may be manufactured utilizing this process.

- Casting can be used for mass production and batch production.

- An item can be cast as one piece, eliminating the metal assembly process.

Choosing the Right Metal Casting Business

For the most constructive outcome when selecting a metal casting company, it is important to compare several businesses using our directory of metal casting businesses. Each metal casting company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with that business for more information or request a quote, Review each metal casting business website using our proprietary website previewer for a better idea of what each company does, Then, use our simple RFQ form to contact multiple metal casting companies with the same form.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services