Die castings made out of magnesium are very lightweight, strong and corrosion resistant. Magnesium is used when weight is a factor and a light, thin product is necessary. It is a non-ferrous metal that exhibits good soundproofing, thermal conductivity and corrosion resistance. It is easily alloyed with other metals and is considered nontoxic in its pure form. Read More…

Precision die castings plus a multitude of related services, including engineering, designing, machining, finishing and assembly, occur at A and B Die Casting. Specializing in low to medium volume solutions, we also offer competitive prices.

Carteret Die Casting has grown from a two man and two machine operation in a tiny 1000 square foot space, to a company that has over 20 state-of-the-art equipment.

Precision Die Casting since 1950. Aluminum die casting and zinc die casting for aerospace, electronic, commercial industries. Turnkey operations from design or your blue print to assembly.

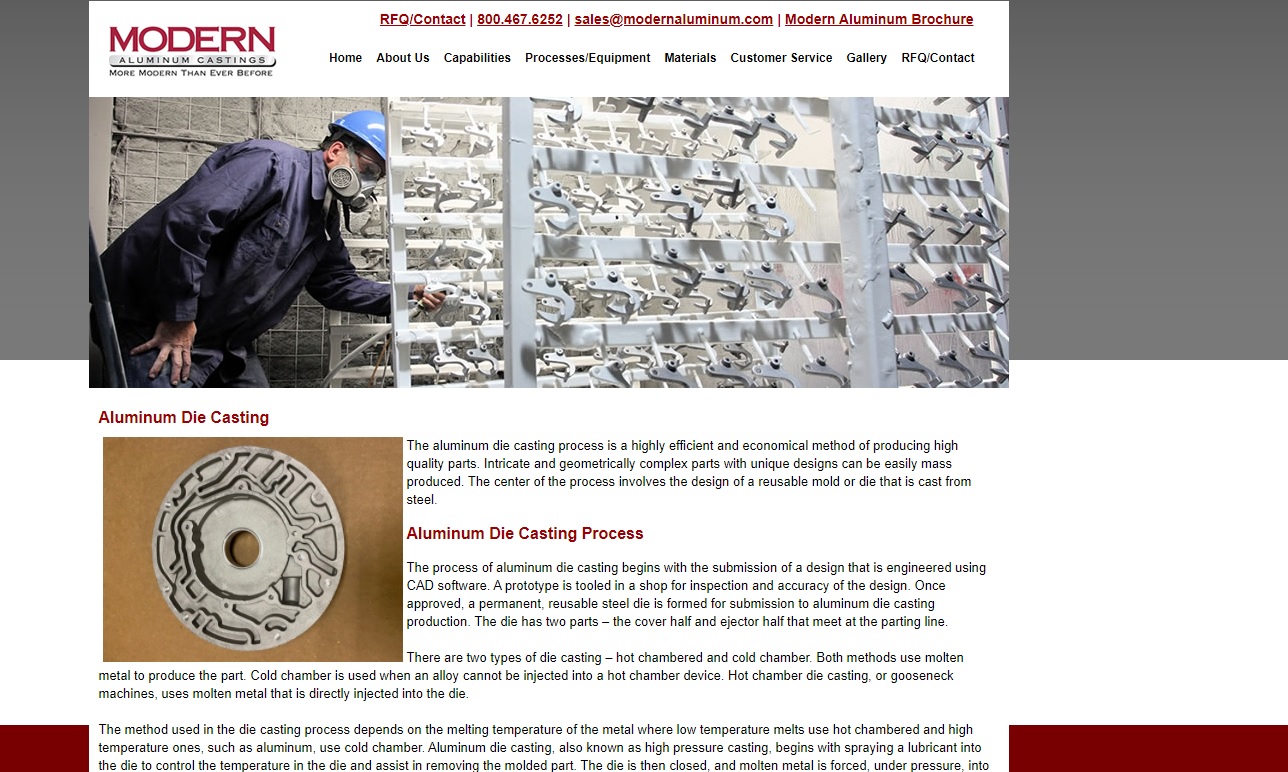

Modern Aluminum Castings offers customers full-service die castings and related capabilities from design to delivery. We work with a large variety of metal options, making us your one-stop source.

Carpenter Die Casting is more than just a die-casting manufacturer; we are your reliable partner in bringing your ideas to life. With decades of experience, a dedication to quality, and a proven track record, we stand ready to contribute our expertise to your next project. Discover the Carpenter Die Casting difference – where innovation meets tradition, and excellence is our standard.

More Magnesium Die Casting Companies

The automotive, electronics, military and aerospace industries use magnesium die cast products, including housings and interior components for computers and electronics, EMI enclosures, small parts for electronic equipment, steering wheel armatures, crash-engineered vehicle parts, power tools, loudspeakers, office electronics, laptops and cell phone hand sets. Since they are so lightweight, magnesium die casting are often used in the construction of automobiles and airplanes, lightening their weight and thus making them faster and reducing their fuel consumption.

Also, electronics and computer equipment casings become very light and easily portable when constructed with magnesium. Die cast magnesium products are a silvery-white color and can be very thin, since magnesium has excellent flow characteristics. It also has 2/3 the density of aluminum, making it much more popular and cost effective.

Magnesium is one of the easiest metals to machine. It has a low melting point and is hot chamber die cut, which is a continuous-flow, efficient process; it is much faster than cold chamber die casting. Molten magnesium will not erode or damage the holding pot, plunger or cylinder. It is the only lightweight metal able to undergo high pressure die casting, which produces very complex parts. The magnesium ingots (raw pellets or scraps) used in die casting are first heated to 150° C and then fed into the holding pot where they are then heated until molten.

Once in liquid form, the magnesium is fed into the shot sleeve by a plunger, which comes in direct contact with the metal. Under high pressure, the magnesium is forced into the mold, coating it completely and evenly. This process can be accomplished with much more ease than it can when casting other metals because magnesium exhibits such a high flow rate. Once solidified, the newly formed part is ejected when a clamping unit releases. If any scrap metal was produced, it can easily be recycled.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services