Aluminum casting is a kind of metalworking procedure that involves pouring molten metal into a mold or form. Aluminum casting is a variant that uses only aluminum and aluminum alloys as the molten metal is poured into the mold. Aluminum castings are utilized to make detailed and complex parts very efficiently. Read More…

A&B Die Casting is a global industry leader in precision aluminum and die castings. We got our start in 1945 by Ben Danthe and today we continue to be a family owned company located in Hercules, California. We focus on producing low to medium volumes of high quality products at competitive prices. Our employees have a flexible, can-do attitude and take on challenging jobs that other die companies ...

Precision Die Casting since 1950. Aluminum die casting and zinc die casting for aerospace, electronic, commercial industries. Turnkey operations from design or your blue print to assembly. Manufacturing services: 3D CAD, mold building, CNC milling and turning, fine finishes, assembly and JIT shipments.

At Modern Aluminum Castings, we are a team of experts in the field of die castings. We have been providing high-quality aluminum casting solutions since 1919, with a commitment to delivering the best possible products and services to our customers. Our die casting products are designed to meet the needs of a wide range of industries, including automotive, aerospace, and industrial...

More Aluminum Casting Companies

What are Aluminum Castings?

In the aluminum casting procedure, aluminum is heated to its molten form and then poured into a mold. The mold must be created with precision since its quality directly impacts the form and surface finish of the completed aluminum casting.

The mold can be made from numerous materials, like tool steel, since aluminum has a lower melting point than steel. Another material that can be a mold for aluminum casting is sand. For this, sand is pressed down to take the shape of the required finished part. Once the sand is shaped, the liquid aluminum is poured into it and left to cool.

Aluminum castings have attributes similar to other aluminum components. Once the casting procedure is done, the aluminum castings quickly make an external layer of aluminum oxide, which helps shield against corrosion.

Aluminum Casting Methods

The different methods of aluminum casting methods include:

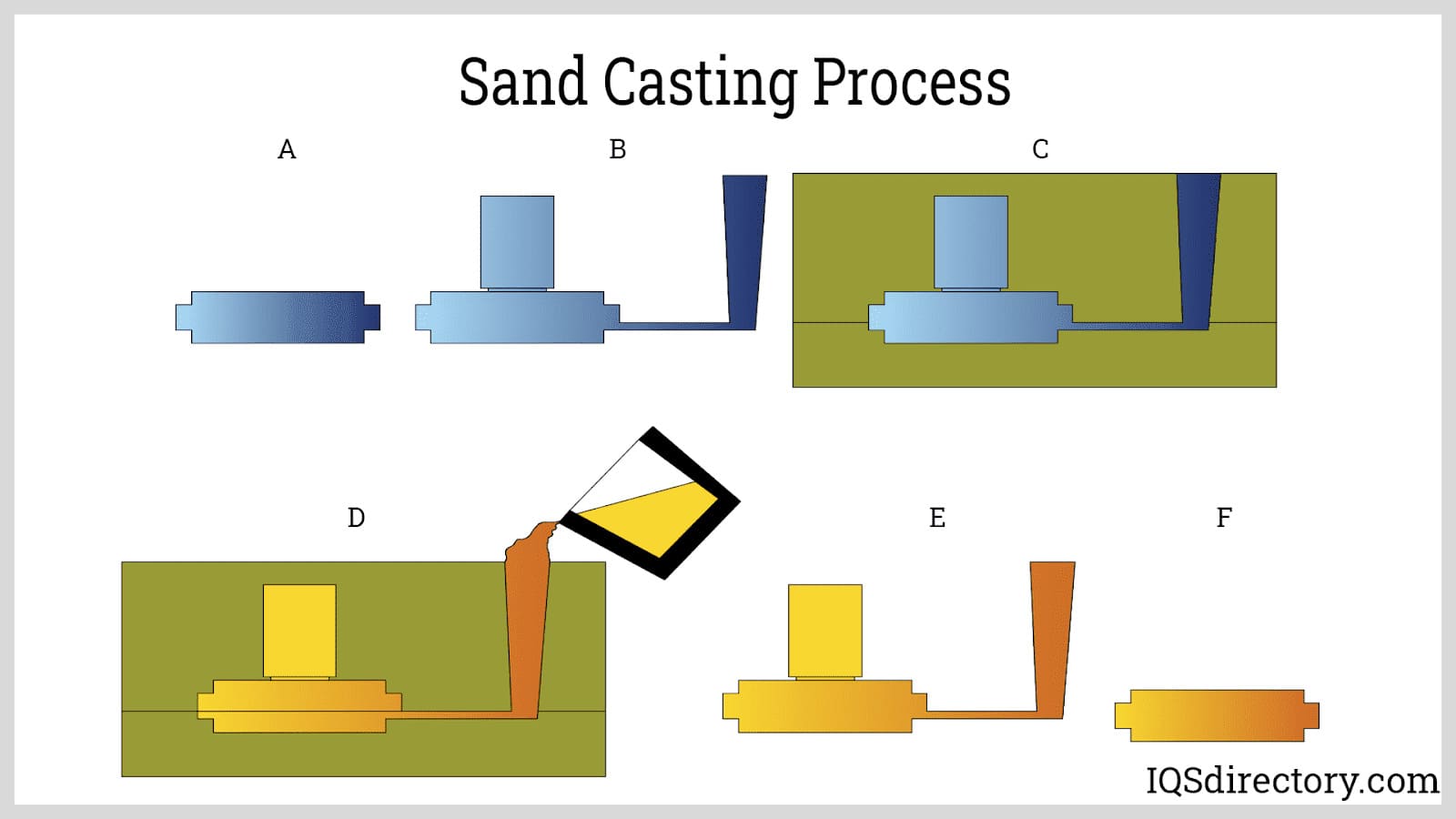

Sand Casting

In aluminum sand casting, mold is made from sand and chemical bonding agents. Patterns are put inside the mold and pressed tightly.

After extracting the pattern, it is formed into a mold cavity which is a replica of the aluminum casting shape.

Liquid aluminum is poured into the mold cavity through a gating system and solidified. As the casting cools off, the caster breaks off the sand mold, and the casting is taken.

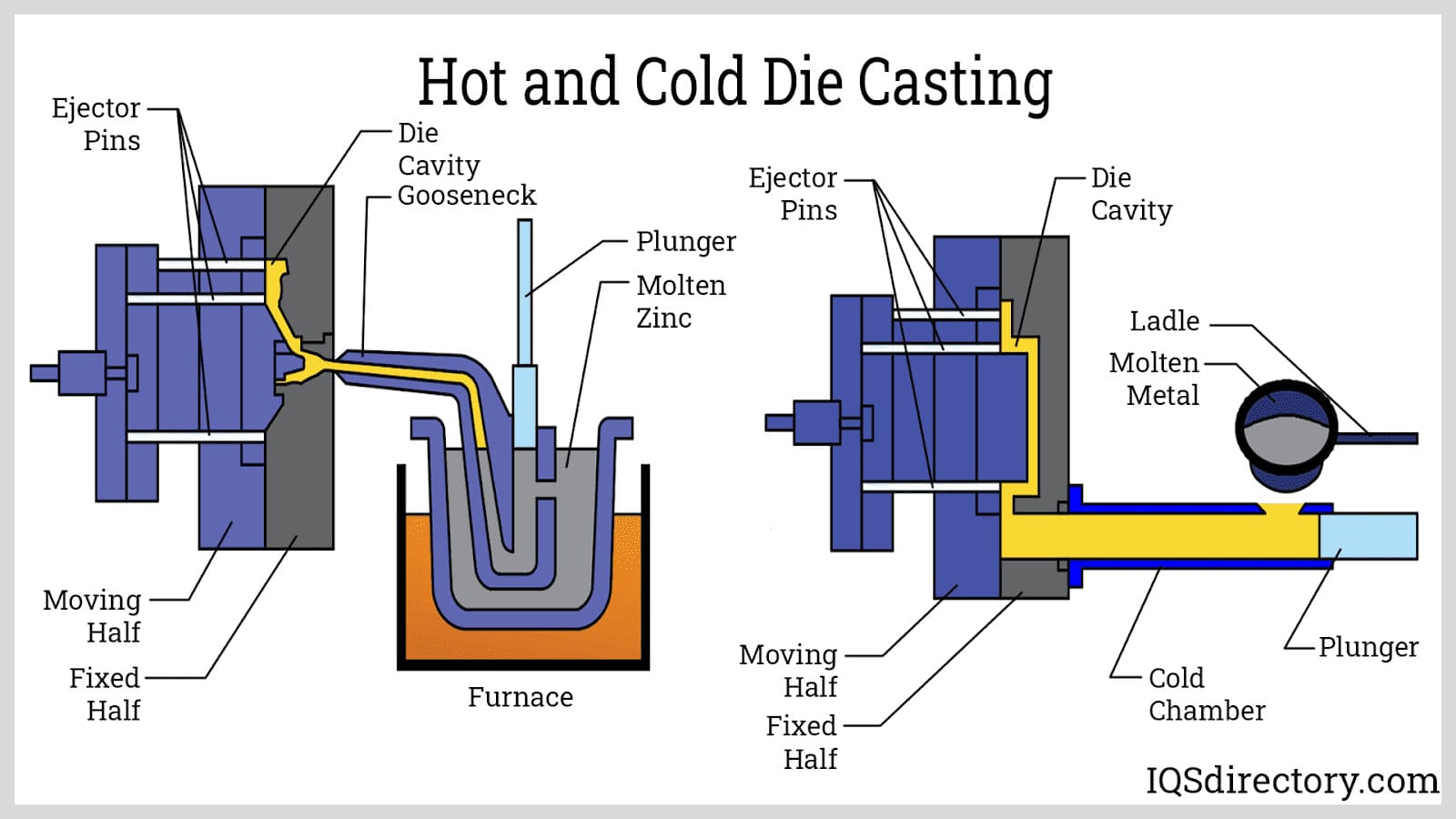

Pressure Die Casting

There are two types of pressure die casting: high pressure die casting and low pressure die casting.

High Pressure Aluminum Die Casting

High pressure aluminum die casting is an aluminum casting procedure that constructs casting pieces by pressing aluminum liquid under high pressure of nearly 1200bar into a steel mold through a cylinder pistol.

Liquid aluminum is pumped at high speeds and solidifies rapidly to make the aluminum casting parts.

Low Pressure Aluminum Die Casting

With low pressure aluminum die casting, the mold is filled with molten metal from a pressure-adjustable crucible, commonly 0.7bar.

The metal hardening furnace is placed below. The liquid aluminum is pumped directly, starting from the base up, to fill the mold.

Aluminum low pressure die casting is perfect for manufacturing aluminum casting pieces with wall thickness starting from 0.12 in (3mm). The volume may be up to 330 lbs (150kg).

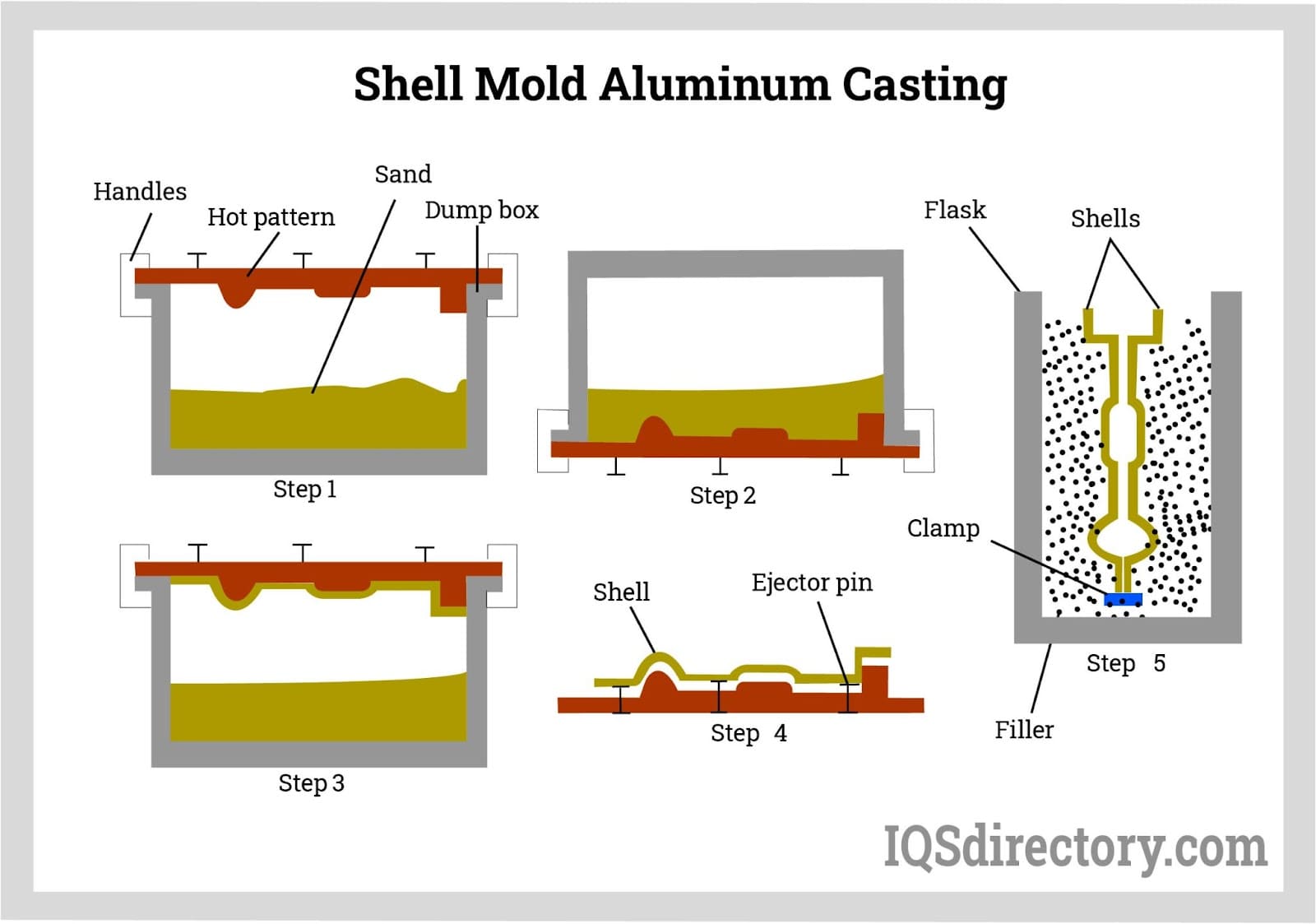

Shell Mold Aluminum Casting

Shell molding is a molding technology with a mold made from thermosetting phenolic resin.

First, the two parts of the patterns are designed and made from metal, then heated and covered with lubrication.

Then the pattern is placed into the thermoset sand compartment prepared above and then turned upside down. The blend of resin sand sticks onto the pattern and hardens, forming a shell.

The pattern is detached, leaving a shell. Two parts of the pattern form two shell molds about 0.39 – 0.78 inches (10-20mm) thick. These two shell molds are attached to form a complete mold. Liquid aluminum is poured into the mold and solidifies into a casting shape.

Shell mold aluminum casting is one of the aluminum casting methods that are perfect for constructing hollow core or die castings.

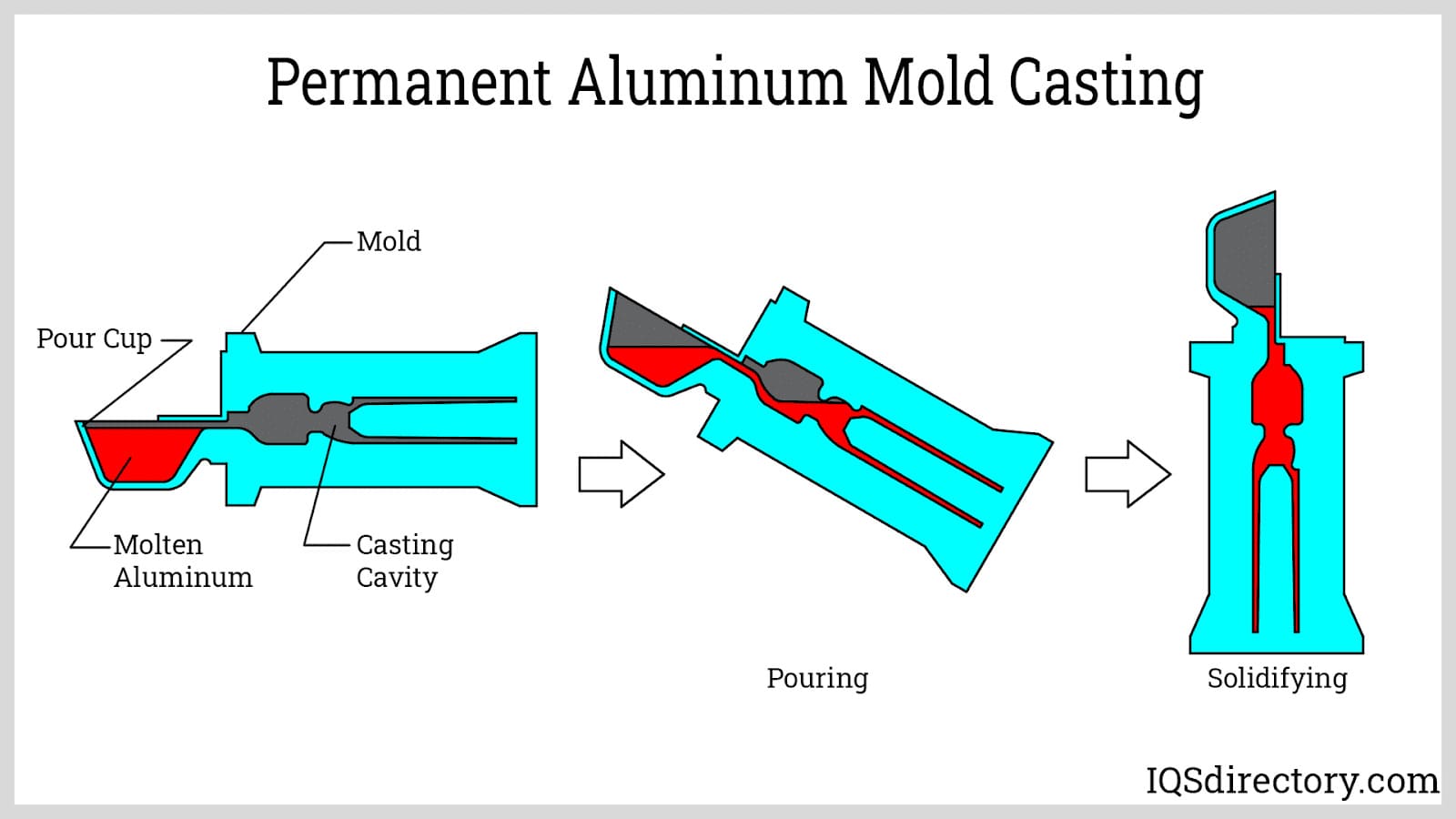

Permanent Mold Aluminum Casting

Also known as metal mold casting, it is one of the aluminum casting methods which uses metal as the mold material, similar to pressure die casting. Accordingly, the molten aluminum is pushed into the mold by its gravity; hence, the pouring speed is fairly low. Due to the metal-made mold, the casting cooling speed is rapid.

Applications of Aluminum Castings

Components of small appliances, lawnmowers, hand tools, and other machines are made from numerous different special aluminum castings.

Casting products are very often utilized by cutlery, the first aluminum product which was made to be available for daily usage.

Automotive and Aircraft parts must be light, and aluminum castings are perfect for such applications. Many applications which require light and non-toxic materials use aluminum castings.

Advantages of Aluminum Castings

Below are the major benefits of aluminum castings:

- Aluminum castings better automotive fuel efficiency by alluding to weight-saving needs.

- They are used in a wide range of infrastructure and networking equipment in computing and telecom industries since RF filter housing and boxing need heat dissipation.

- With minimal weight in handheld devices, they offer EMI/RFI shielding, durability, and rigidity.

- Even in high-temperature environments, aluminum has excellent electrical shielding and performance; hence’ aluminum die casting is perfect for electronic housings and connectors.

Choosing the Right Aluminum Casting Company

For the most constructive outcome when selecting an aluminum casting company, it is important to compare several businesses using our directory of aluminum casting companies. Each aluminum casting company has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with this business for more information or request a quote. Review each aluminum casting business using our proprietary website previewer for a better understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple aluminum casting companies with the same form.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services