To cast aluminum and aluminum products, engineers work in aluminum foundries. Foundries are factories that produce metal castings, so, in short, aluminum foundries are aluminum casting factories. Foundries also commonly process cast iron, bronze, brass, steel, magnesium and other metals. Read More…

Precision die castings plus a multitude of related services, including engineering, designing, machining, finishing and assembly, occur at A and B Die Casting. Specializing in low to medium volume solutions, we also offer competitive prices.

Carteret Die Casting has grown from a two man and two machine operation in a tiny 1000 square foot space, to a company that has over 20 state-of-the-art equipment.

Precision Die Casting since 1950. Aluminum die casting and zinc die casting for aerospace, electronic, commercial industries. Turnkey operations from design or your blue print to assembly.

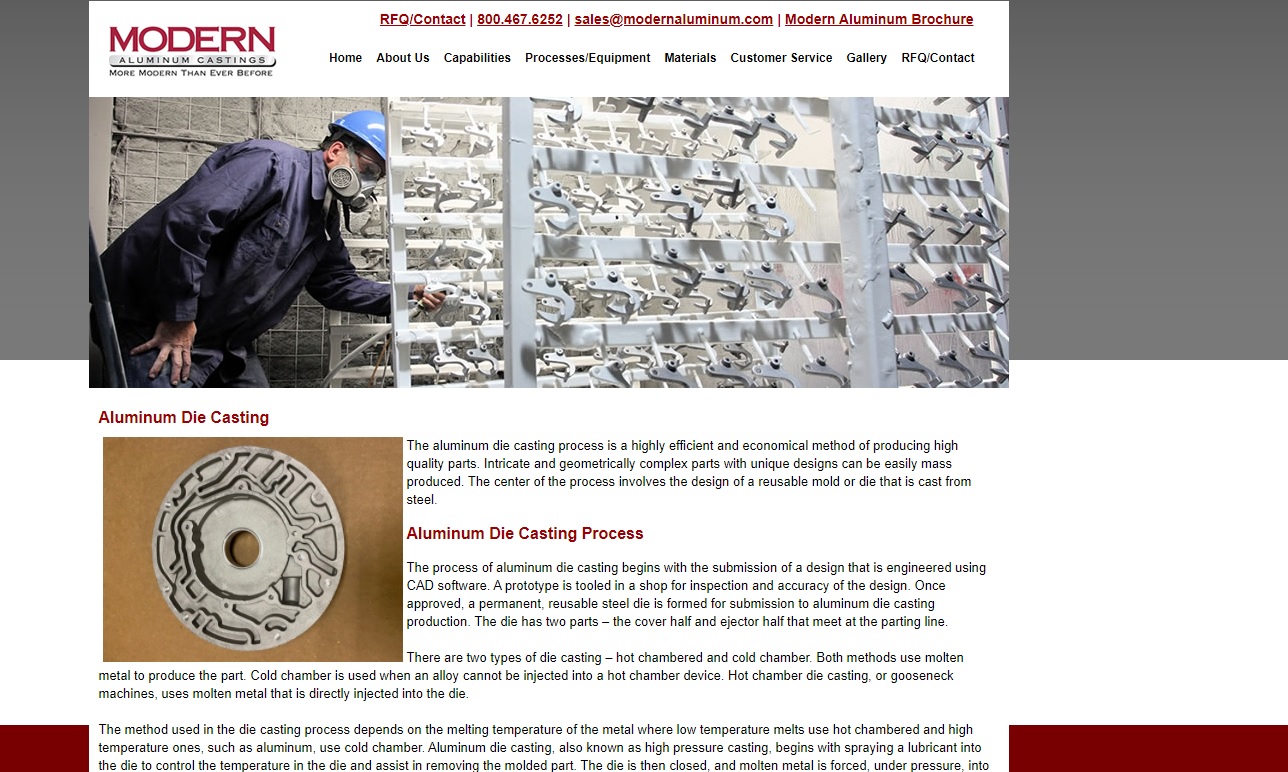

Modern Aluminum Castings offers customers full-service die castings and related capabilities from design to delivery. We work with a large variety of metal options, making us your one-stop source.

Carpenter Die Casting is more than just a die-casting manufacturer; we are your reliable partner in bringing your ideas to life. With decades of experience, a dedication to quality, and a proven track record, we stand ready to contribute our expertise to your next project. Discover the Carpenter Die Casting difference – where innovation meets tradition, and excellence is our standard.

More Aluminum Foundry Companies

Aluminum is cast by melting it into a liquid form, pouring it into a mold and then, after the aluminum cast solidified and cools, removing it from the mold or cast. It may be cast into various shapes and sizes. Aluminum foundries use various types of source metal to charge the furnace, including virgin material, external scrap and internal scrap. External scrap is material sourced from other forming processes like punching, forging or machining. Internal scrap consists of risers, gates, defective castings and other extraneous oddments metal produced within the facilities.

There are several steps that need to be taken to prepare the material for casting. First the metal used to charge the furnace is melted and refined to remove harmful gases and elements from the molten metal.

The chemistry of the molten metal is then adjusted to fit the specifications of the intended final product, and then tapped into a transport vessel. Furnaces are used to melt the charge metal, and depending on the requirements of the manufacturer, a foundry's furnace attributes, such as size, weight, temperature and heat sources, can all vary to accommodate specific requirements. Aluminum foundries have furnaces specifically designed for aluminum, but can still vary based on the volume of aluminum being cast.

Aluminum foundries most commonly use reverberatory, gas heated crucible or electric resistance furnaces. Sometimes, hydrogen or other gases get into the casting, either by physical entrapment or chemical reaction. If this in the case, it is removed via de-gassing. Aluminum castings are most often formed by die casting, but may also be made via permanent mold casting or sand casting.

Casting aluminum presents several advantages. Aluminum is lightweight, retains strength at high temperatures and has high dimensional stability for complex shapes and thin walls, good corrosion resistance, good mechanical properties and high thermal and electrical conductivity. Aluminum castings enjoy widespread usage in the auto industry and in the home. More than half of the aluminum used in cars is made in aluminum foundries and cast aluminum transmission housings and pistons have frequently been used in trucks and cars since the early 1900s.

Additionally, components of lawn mowers, hand tools, small appliances and other machinery are produced from shapes cast in aluminum foundries all over the world. At home, you will find the most cast aluminum in your kitchen cabinets. In fact, cookware was the first aluminum product produced for everyday use.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services