Die casting is a type of metal casting, characterized by its process of forcing molten metal into a mold cavity under high pressure. This mold cavity is made using two hardened tool steel dies that have been machined into shape, working much like an injection mold. Read More…

Precision die castings plus a multitude of related services, including engineering, designing, machining, finishing and assembly, occur at A and B Die Casting. Specializing in low to medium volume solutions, we also offer competitive prices.

Carteret Die Casting has grown from a two man and two machine operation in a tiny 1000 square foot space, to a company that has over 20 state-of-the-art equipment.

Precision Die Casting since 1950. Aluminum die casting and zinc die casting for aerospace, electronic, commercial industries. Turnkey operations from design or your blue print to assembly.

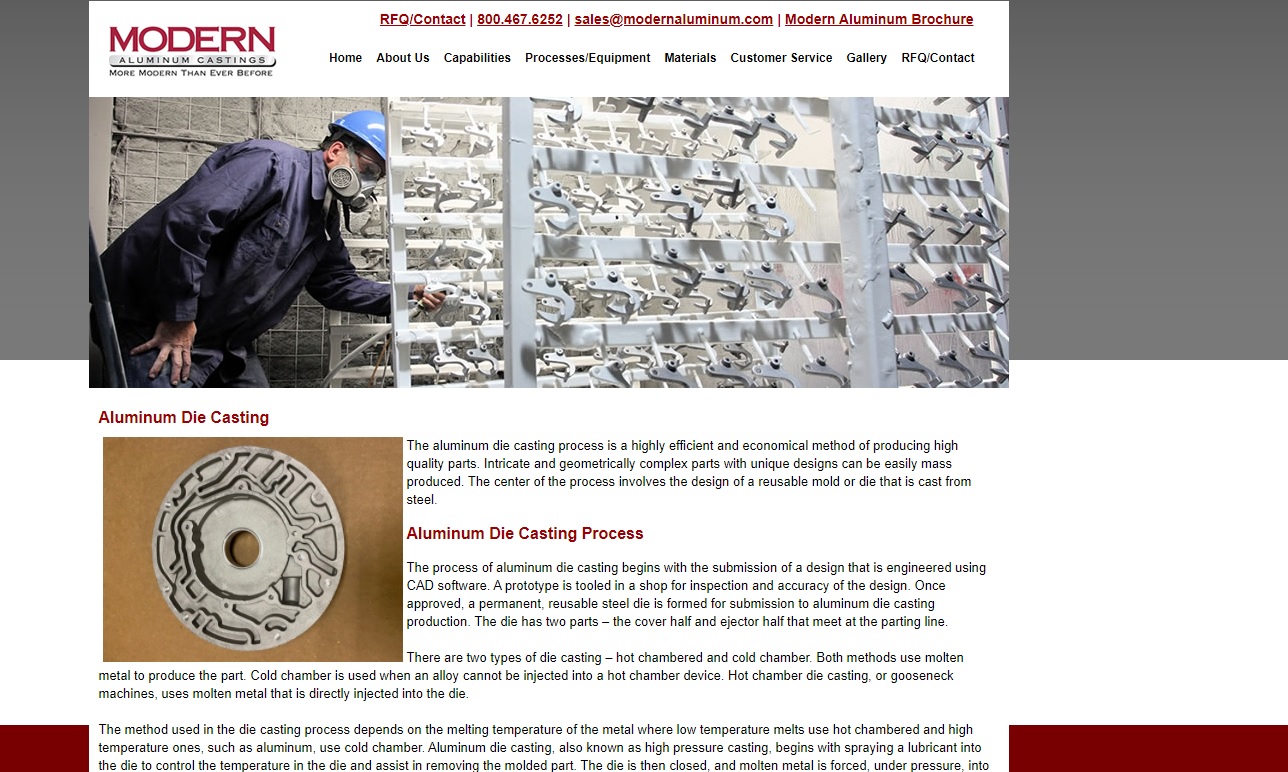

Modern Aluminum Castings offers customers full-service die castings and related capabilities from design to delivery. We work with a large variety of metal options, making us your one-stop source.

Carpenter Die Casting is more than just a die-casting manufacturer; we are your reliable partner in bringing your ideas to life. With decades of experience, a dedication to quality, and a proven track record, we stand ready to contribute our expertise to your next project. Discover the Carpenter Die Casting difference – where innovation meets tradition, and excellence is our standard.

More Miniature Die Castings Companies

Most die castings are formed from non-ferrous metals, such as zinc, copper, aluminum, magnesium, lead, pewter and tin-based alloys. Miniature die castings are made under a similar casting process. Miniature die casting, however, employs machines and dies specifically designed for the production of small parts.

This casting process presents quite a few advantages. Miniature die castings are capable of holding very tight tolerances as-cast, up to approximately +/- .001", with walls as thin as .020" and parts as heavy as .75 pounds. Miniature die casting allows for complex net shape, flash-free parts with all kinds of unique features and specified tolerances. It also requires no post-casting machining and eliminates the necessity for gate removal through automated degating or part-on-part deburring.

Additionally, tooling costs are much lower than conventional die cast tooling costs. This is because this type of die casting does not require a trim tool, and the tools it does require are much smaller. With possible cycle numbers averaging up to 1MM, miniature die castings also offer the advantage of long life. Fast cycle times contribute to the low cost of miniature die cast parts. In comparison to conventional die castings, miniature die castings cost pennies on the dollar.

Miniature die castings can be used in a variety of industries, such as medical, dental, electronics, transportation, recreation, alternative energy and general industry. Possible applications for these castings are nearly endless. Just a few examples include: tank adaptors, lock components, valve assemblies and electronic components such as jam nuts. Manufacturers generally offer many standard and custom options for specification and application requirements. These options may relate to casting size, section thickness, variation in section thickness, draft angle, ejector pin marks and threads, gears and gear teeth. Parting line selection is a decision made by the caster, who will consider factors including ejection, configuration coring, finish speculations, gating, type of die and flash removal. Partnering with the right team will ensure miniature die castings that will serve you for years to come.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services