Le Sueur Incorporated

Le Sueur IncorporatedRequest A Quote

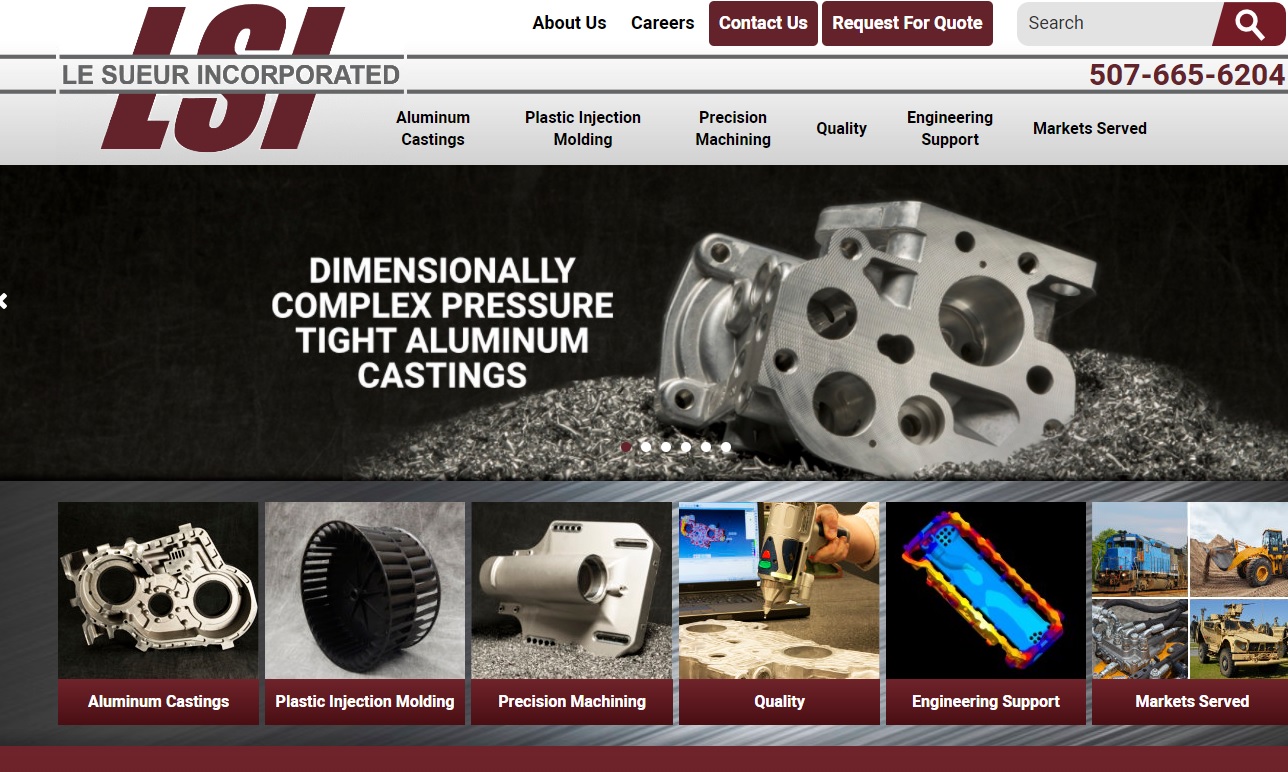

Le Sueur, MN | 507-665-6204Le Sueur Incorporated, located in Le Sueur, Minnesota, is a prominent die casting company with a rich history in the industry. We have built a strong reputation by serving over 200 die casting clients with excellence. Our expansive 274,000 square foot facility positions us as a leading die casting distributor, allowing us to meet the diverse needs of our customers effectively. Our core specialization lies in die castings, where we offer a wide range of high-quality products that meet stringent industry standards. With our expertise in sand casting and aluminum casting, we ensure the production of durable and reliable components for various applications. To complement our die casting capabilities, we provide a comprehensive range of services to add value to our customers' products. One of our notable services is plastic injection molding, which enables us to manufacture top-quality plastic components. We employ advanced molding techniques and state-of-the-art equipment to ensure efficiency and precision throughout the process. We understand the significance of prototyping in product development, and thus, offer prototyping services to help our clients visualize and refine their designs before proceeding to full-scale production. This iterative process allows for modifications and optimizations, resulting in products that meet exact specifications and requirements. Our capabilities extend to permanent molding as well. This process is utilized for casting non-ferrous metals, and our expertise ensures the production of durable and precise components that withstand rigorous applications. At Le Sueur Incorporated, we pride ourselves on our precision machining department, equipped with advanced machinery. Our team of skilled professionals leverages their expertise to deliver precise machining services, ensuring the final products meet tight tolerances and complex shapes. Furthermore, our company excels in design engineering, offering comprehensive support to our clients throughout the product development process. We collaborate closely with customers to optimize designs, identify cost-effective solutions, and ensure manufacturability.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services