Lakeside Casting Solutions

Lakeside Casting SolutionsRequest A Quote

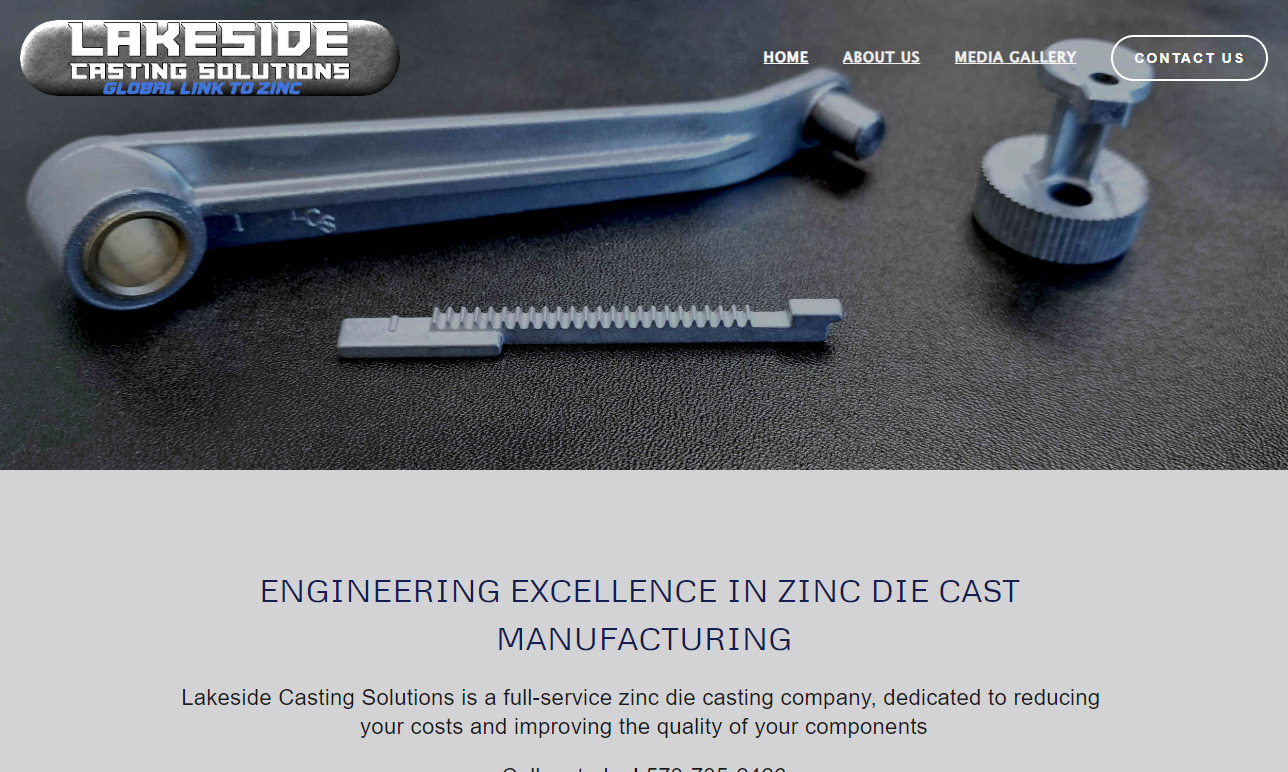

Monroe City, MO | 573-735-2426Lakeside Casting Solutions is a reputable manufacturing company located in Monroe City, Missouri, specializing in the production of custom zinc casted components. With a strong focus on innovation and advanced casting techniques, we have established ourselves as a leading provider of high-quality zinc castings. Our unique expertise in four-slide tooling technology sets us apart, allowing us to cast undercuts and incorporate special features that are typically unobtainable with conventional die casting methods. At Lakeside Casting Solutions, we take pride in our comprehensive capabilities that enable us to produce a wide range of castings. Whether you require small, intricate components or larger, more substantial parts, we have the flexibility to meet your specific needs. Our advanced machinery and skilled workforce allow us to produce castings ranging from ½ a gram up to 2 pounds, ensuring that we can handle diverse project requirements. As specialists in hot chamber zinc alloys, we work with various alloys including #2, 3, 5, 7, ZA-8, Accuzinc, and Ezac. Our in-depth knowledge of these materials, coupled with our state-of-the-art equipment, enables us to deliver zinc castings with exceptional dimensional accuracy, surface finish, and mechanical properties. We continually invest in research and development to stay up-to-date with the latest advancements in zinc casting technology, ensuring that our customers benefit from the most efficient and reliable solutions available. In addition to our casting capabilities, Lakeside Casting Solutions offers a comprehensive range of services to meet all your project requirements. We provide post-machining and assembly services, allowing us to deliver fully finished components that are ready for immediate use. Our skilled technicians and engineers have the expertise to perform precise machining operations, ensuring that the final products meet your exact specifications. Lakeside Casting Solutions operates under an ISO Certified 9001-2015 quality management system. This certification reflects our dedication to maintaining the highest standards of quality control and customer satisfaction. We strive to consistently exceed customer expectations by implementing rigorous quality assurance measures throughout our manufacturing processes. When you choose Lakeside Casting Solutions as your zinc casting partner, you can expect exceptional quality, precision, and reliability. Contact us today to discuss your casting requirements, and let us demonstrate how our expertise and capabilities can contribute to the success of your projects.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services