Technical Die Casting, Inc.

Technical Die Casting, Inc.Request A Quote

Stockton, MN | 800-525-3168https://www.tech-die-casting.com/

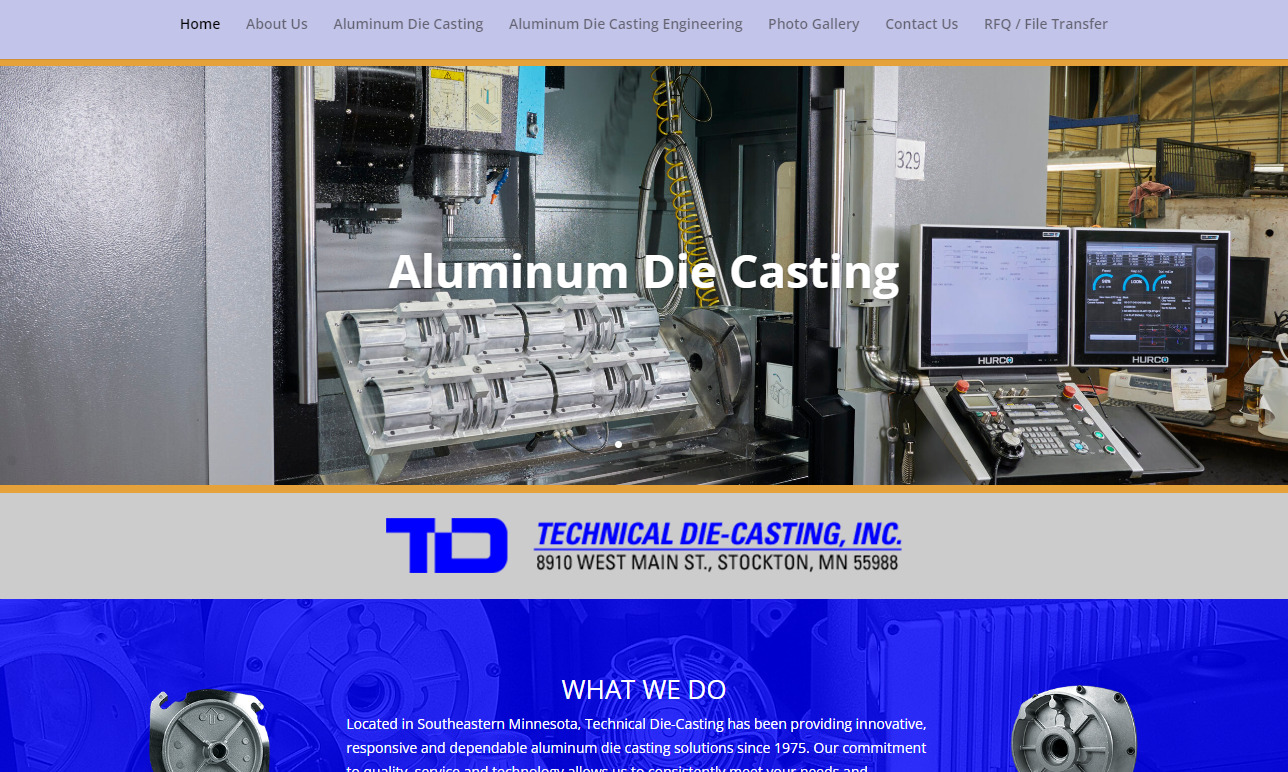

Technical Die Casting, Inc. is a leading manufacturing company located in Stockton, Minnesota. With over 40 years of experience in the industry, we have established ourselves as a trusted provider of high-quality aluminum die casting solutions. At Technical Die Casting, Inc., we are committed to delivering exceptional products, services, and capabilities to our valued customers. We specialize in aluminum die casting, utilizing advanced techniques and state-of-the-art technology to create precision-engineered components. Our products are designed to meet the diverse needs of various industries, including automotive, aerospace, electronics, consumer goods, and more. From intricate parts to complex assemblies, we have the expertise to deliver customized solutions that meet your specific requirements. Technical Die Casting, Inc. offers a comprehensive range of services to support our customers throughout the entire manufacturing process. Our team of skilled professionals is equipped to assist you at every stage, from design and prototyping to production and finishing. We strive to provide efficient and cost-effective services that streamline your production timeline and maximize the quality of the end product. At Technical Die Casting, Inc., we boast a state-of-the-art facility that is fully equipped with cutting-edge machinery and equipment. Our manufacturing capabilities enable us to produce high-precision, complex aluminum die castings in various sizes and configurations. We have a dedicated team of engineers and technicians who possess extensive knowledge and expertise in the die casting process, ensuring that each component meets the highest standards of quality and performance. When you partner with Technical Die Casting, Inc., you gain access to a world of endless possibilities. Our commitment to innovation and continuous improvement allows us to explore new frontiers in aluminum die casting technology. We embrace challenges and thrive on delivering groundbreaking solutions that surpass industry standards. Whatever your project requirements may be, we are dedicated to finding the best possible solution to meet your needs. At Technical Die Casting, Inc., we prioritize customer satisfaction and strive to provide the highest level of service. Our team understands the importance of delivering products on time and within budget. We work closely with our customers, offering personalized attention and tailored solutions to ensure that your project is a success. Our dedication to quality service has earned us a reputation for excellence in the industry. For more information about our products, services, and capabilities, we encourage you to contact Technical Die Casting, Inc. today. Our knowledgeable team is ready to assist you and help bring your vision to life. Discover the endless possibilities that await with Technical Die Casting, Inc.!

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services