C. Palmer Die Casting, Inc.

C. Palmer Die Casting, Inc.Request A Quote

Oakland, MD | 301-334-9100https://cpalmerdiecastinginc.com

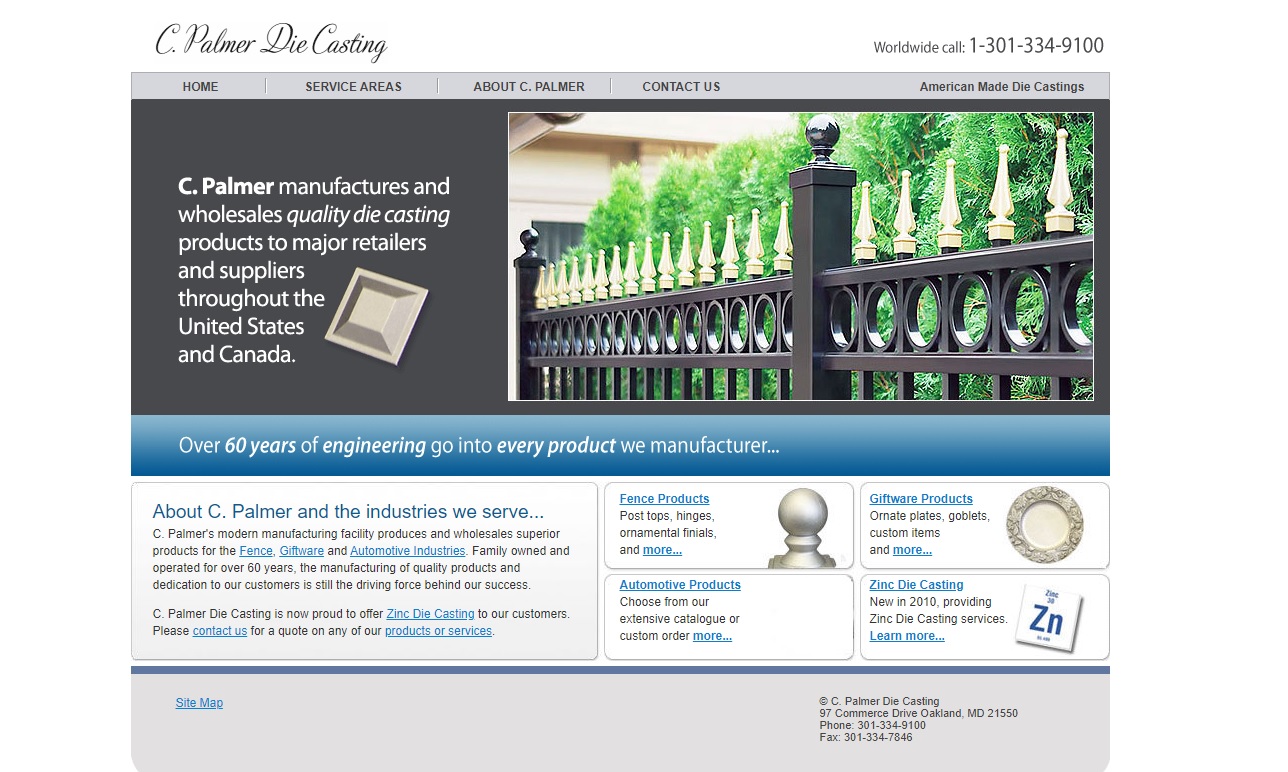

C. Palmer Die Casting, Inc. is a reputable die casting manufacturer based in Oakland, Maryland. With a rich history spanning over six decades, our company has established itself as a leader in the industry, specializing in the production of high-quality die castings, particularly aluminum castings. As a family-operated business, we take great pride in our legacy and the long-standing relationships we have built with our dedicated customers who continue to rely on our exceptional die casting services. At C. Palmer Die Casting, we understand the importance of delivering superior products to meet the unique needs of our clients. Our state-of-the-art facility is fully equipped with an in-house tool and die facility, allowing us to provide comprehensive die casting solutions from start to finish. This integrated approach ensures that our customers receive the highest level of precision, quality, and efficiency in every aspect of their die casting projects. One of our key strengths lies in our versatility in producing die castings of varying sizes and complexities. Our casting capabilities range from 1 ounce to over 6 pounds, enabling us to cater to a wide range of industries and applications. Whether it's small intricate parts or large structural components, we have the expertise and equipment to deliver exceptional die castings that meet the strictest specifications and quality standards. As a die casting company, we prioritize the use of aluminum as a primary material due to its exceptional properties, including lightweight, high strength-to-weight ratio, excellent corrosion resistance, and superior thermal conductivity. These qualities make aluminum castings ideal for numerous industries such as automotive, aerospace, electronics, and more. However, we are also capable of working with other materials based on our clients' requirements and specifications. At C. Palmer Die Casting, we value long-term partnerships and strive to build strong relationships with our clients based on trust, reliability, and exceptional customer service. We are constantly investing in advanced technologies and staying updated with the latest industry trends to remain at the forefront of die casting innovation.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services