Bardane Manufacturing Company

Bardane Manufacturing CompanyRequest A Quote

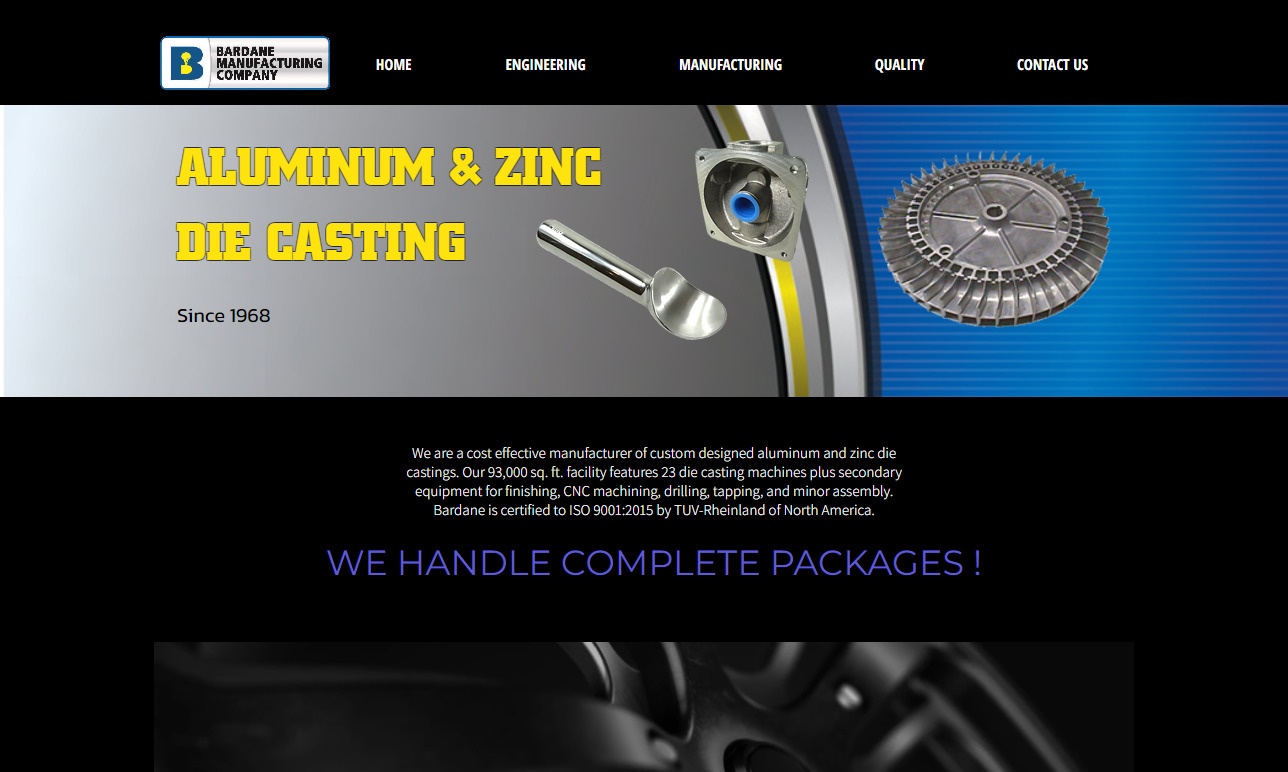

Jermyn, PA | 570-876-4844Bardane Manufacturing Company, based in Jermyn, Pennsylvania, is a prominent leader in the die casting industry. With a strong focus on providing high-quality custom-designed parts, Bardane Manufacturing is renowned for its exceptional products and services. The company specializes in high-pressure aluminum die castings and zinc die castings, catering to a diverse range of industries and applications. One of Bardane Manufacturing's core strengths lies in die casting. Their expertise encompasses both high-pressure aluminum die casting and zinc die casting. By leveraging advanced techniques and state-of-the-art equipment, the company ensures the production of top-quality parts that meet stringent standards for dimensional accuracy, durability, and performance. In addition to die casting, Bardane Manufacturing offers a comprehensive suite of value-added services. Their machining capabilities are exceptional, allowing for precise and accurate finishing of parts according to customer specifications. The company's skilled technicians utilize cutting-edge equipment to ensure the highest standards of precision and functionality. Bardane Manufacturing also provides assembly services, streamlining the production process for their clients. Their experienced team is well-equipped to handle complex assembly tasks, ensuring efficiency and timely completion of projects. By offering assembly services, Bardane Manufacturing simplifies the supply chain for their customers, providing a seamless one-stop solution for their assembly needs. Furthermore, Bardane Manufacturing excels in finishing services. They understand the importance of aesthetic appeal and offer a range of surface treatments, including polishing, painting, powder coating, and anodizing. These finishing touches not only enhance the appearance of the parts but also provide protection against corrosion, ensuring long-lasting performance and visual appeal. Bardane Manufacturing's capabilities are supported by their commitment to custom design. Their experienced team collaborates closely with clients to understand their specific requirements and deliver tailored solutions that meet their needs. The company's advanced equipment and technology further enhance their capabilities, enabling them to achieve precision, efficiency, and consistent quality throughout their manufacturing operations.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services